Manufacturing process

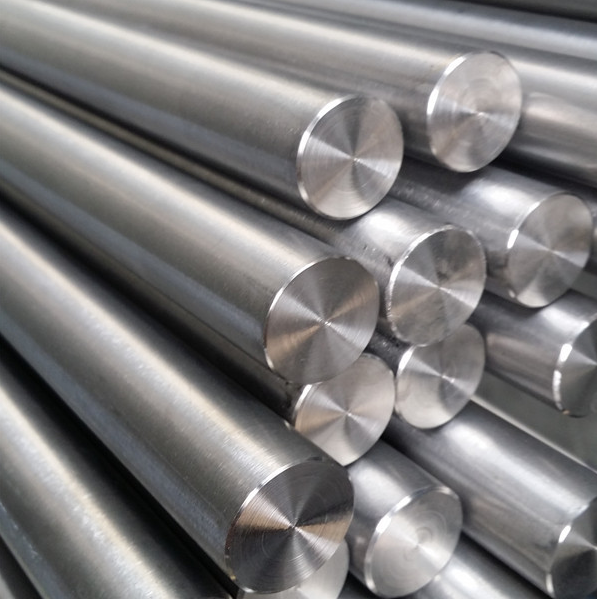

The manufacturing process of molybdenum rod is similar to that of molybdenum plate.

It is produced by shaping, sintering, forging, straightening and polishing.

Characteristics

The molybdenum rod is characterized by high melting point, good ductility, excellent elongation.

It appears black, alkali washing, lathing and grinding.

Applications

Molybdenum rod is usually used as components in electron vacuum devices, gas tube and bulbs with purity requirement. Molybdenum rod also can be used as grid siderod, support of electron tubes and lamps.

Moly rod can be applied for producing electric light source parts and electric vaccuum components;

Moly rod is used to make heating elements and refractory parts in high temperature furnaces and is used in glass and glass fiber industry.

Molybdenum rod can serve a long life in melted glass liquid at 1300℃. Molybdenum rods are used as electrodes in the field of rare earth metal industry.molybdenum alloy rod , molybdenum carbide rod and etc. Which based on the degree of purity of molybdenum. The molybdenum content of pure molybdenum rod is over 99.9%.

Molybdenum Trioxide

Molybdenum trioxide is the essential element in making molybdenum rod, molybdenum alloy rod and other molybdenum compound.

Molybdenum as matrix compound with other non-ferrous metals such as titanium, zirconium, hafnium, tungsten and others to make up molybdenum alloy rod. Molybdenum, carbon, hydrocarbon or carbon monoxide active over 800℃ to form the molybdenum carbide, for further process, the molybdenum carbide rod comes out.

Forged moly rod, swaged moly rod, lathing moly rod, straightened moly rod and polished moly rod are available in Aceon.

We are able to supply molybdenum rod according to your special requests. Samples are available.We offer several types of molybdenum rods and now we could make the diameter of molybdenum is over 2.o meters.

Properties and specifications:

Molybdenum rod has high melting point and good thermal conductivity. At high temperature, it can not be easily oxidated and distorted. Moly rod supplied by Aceon has no obvious crack, burr, peel and other defects affecting the further uses. We also provide molybdenum coating.

| As-furnished | diameter range(mm) | min.length |

| Swages/forged | 3.0-16.0 | 400 |

| Straightened | 0.8-3.0 | 1000 |

| Ground | 0.8-2.5 >2.5-5.0 >5.0-8.0 >8.0-12.0 >12-40 | 1000 800 500 300 200 |