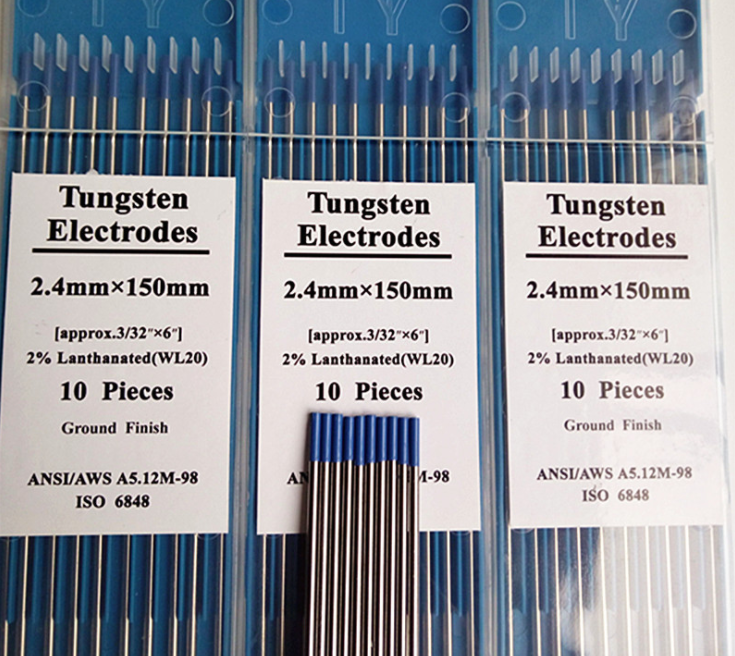

2% Lanthanated Tungsten Electrode Rod is a wonderful product for TIG welding.

The characteristics of the 2% Lanthanum Tungsten Electrode Rod of our company:

1, select La2O3

The oxide La2O3 of the rare earth element La has a six square structure and a higher melting point (2217C). After decomposition of 600C-700C, La becomes a non coherent particle in tungsten. These particles can effectively promote the crystallization and grain growth and growth of alloys, thereby improving the high temperature strength and creep properties of tungsten alloys, and improving the ductility of alloys at low temperature. The research shows that the initial recrystallization temperature of pure tungsten is 1360C, and the initial recrystallization temperature of tungsten and lanthanum alloy can be increased to 2200C. The tungsten ductile wire annealed for 5 minutes has a ductility of 3 times that of WAl wire, while the seismic performance increases 3-5 times.

If we select lanthanum nitrate to mix with tungsten powder, there is a certain problem of pollution, the amount of quantity become larger and the cost become higher.

2, research and choose the reasonable process

The doping of La2O3 in WO2 can ensure the even and La2O3 loss of doping by reduction, mixing and sieving. By using one and two vertical melting technology (sintering), the dispersed distribution of La in tungsten is uniform, and the tungsten and lanthanum alloy product is stable.

As the high temperature strength of the Lanthanated Tungsten Electrode is very good, it is necessary to use a higher process temperature in the process of pressure processing. The blank opening temperature of pure tungsten is 1450C+50C, and the blank opening temperature of the tungsten lanthanum alloy is 1600C+50C. Pure tungsten does not need intermediate annealing, while tungsten lanthanum alloy needs annealing at 10-11. It can solve the subsequent pressure problem of tungsten and lanthanum alloy better, improve the yield and reduce the production cost. After ten years of practice, a complete set of mature production technology and batch production have been obtained.

Our company’s annual production capacity is 40 tons, and there are a large number of export orders. Our company adopts WO2 doped pressure processing technology. It has unique characteristics, mature technology and stable product quality. The inspection standard has been referred to the AMS-T-21014 standard of the United States.

The products of the Lanthanated Tungsten Electrode produced by our company are tested by 725 testing centers in Luoyang, and their performance has reached or exceeded the AMS-T-21014 standard in the United States.

Tungsten – thorium alloy has radioactivity, and Lanthanated Tungsten Electrode is an ideal substitute for tungsten thorium alloy, which can reduce radioactive contamination.

Awesome post! Keep up the great work! 🙂

Excellent post! We are linking to this great article on our website.

Keep up the great writing.

I used to be able to find good info from your articles.

I was able to find good advice from your blog, thanks!

Hello! Would you mind if I share your blog with my facebook group?

There’s a lot of folks that I think would really appreciate your content.

Please let me know. Thank you

As a Newbie, I am constantly browsing online for articles that can help me. Thank you

Great content! Super high-quality! Keep it up! 🙂

Interesting blog! Is your theme custom made or did you download it from somewhere? A theme like yours with a few simple adjustements would really make my blog stand out. Please let me know where you got your theme. Bless you

Valuable info. Lucky me I found your website by accident, and I’m shocked why this accident did not happened earlier! I bookmarked it.

fantastic publish, very informative. I’m wondering why the opposite experts of this sector don’t realize this. You should proceed your writing. I’m confident, you’ve a huge readers’ base already!