Brief introduction:

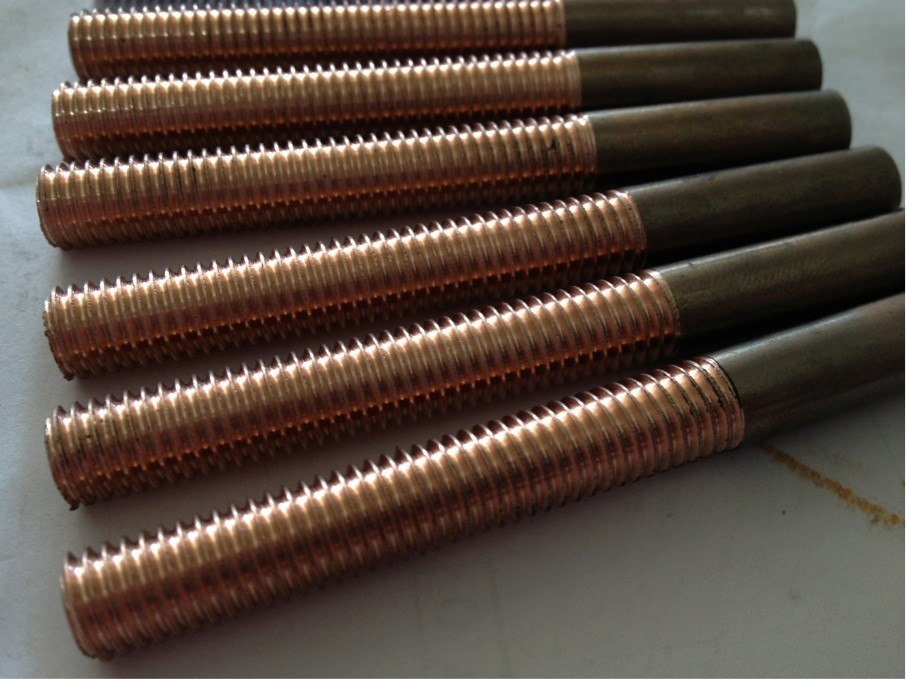

What is Cu-W alloy? Cu-W alloy is copper and tungsten alloy. The copper content is 10%~50% in Cu-W alloy. Our Tungsten Copper Alloy is produced by Impermeable Method.

Manufacturing process:

Cu-W alloy, also called tungsten-copper alloy. It is common to adopt powder alloy technology to make of Tungsten Copper Alloy. The process includes powder mixing, pressing to shapes, sintering and cold processing. With 22 years experience in dealing refractory metal, we have our own factory and perfect production line.

Applications:

Cu-W has a wide application. It is mainly used to manufacture switch contact of high-voltage electrical appliances, rocket nozzle throat liner and sternpost rudder, and other high temperature components and parts. In addition, it also can be used to make electrode, high temperature mold and other high heat and electrical conductive parts. Sometimes, it is applied to make sealed cap for transistors sealing welder, contactor materials for high voltage switches and electrodes for spark-erosion machine tool, etc.

Properties:

Tungsten Copper Alloy features good heat and electrical conductive, high temperature resistance strength and ductility.

Characteristics:

Tungsten Copper Alloy has good electric conductivity, excellent high temperature strength and plasticity.

The Chemical Compositions and Main Properties of Cu-W Alloy in Chinese National Standard GB/T 8320-2003:

| Chemical Composition(%) | Density (g/cm3) |

Hardness (HB) |

Resistivity (μΩ·cm) |

IACS% | Bending strength Mpa |

||

| W | Cu | Other | |||||

| 70±2 | 30±2 | ≤0.5 | ≥13.80 | ≥175 | ≤4.1 | ≥42 | 790 |

| 75±2 | 25±2 | ≤0.5 | ≥14.50 | ≥195 | ≤4.5 | ≥38 | 885 |

| 80±2 | 20±2 | ≤0.5 | ≥15.15 | ≥220 | ≤5.0 | ≥34 | 980 |

| 85±2 | 15±2 | ≤0.5 | ≥15.90 | ≥240 | ≤5.7 | ≥30 | 1080 |

| 90±2 | 10±2 | ≤0.5 | ≥16.75 | ≥260 | ≤6.5 | ≥27 | 1160 |

Our density:

| Type | Density (g/cm3) |

| CuW70 | 14.3 |

| CuW75 | 14.9 |

| CuW80 | 15.6 |

| CuW85 | 16.4 |

| CuW90 | 17.3 |

It is easy to find out that the density of our products is much higher than the National Standard GB/T 8320-2003. The high-density shows the processing technology of our products is superb. Density also plays an important role in loss rate and service life of product.

Aceon is the biggest Cu-W alloy suppliers in China. Our Tungsten Copper Alloy supplied for Porsche, Volkswagen and other top enterprises in the world. The market share of tungsten copper alloys in Germany is up to 30%.

Hey there are using WordPress for your blog platform?

I’m new to the blog world but I’m trying to get started and set up my own. Do you require any html coding expertise to make your own blog?

Any help would be greatly appreciated!

Your place is valueble for me. Thanks!?